Custom Designed LCD Panels

- Technology offered

TN, HTN, EBTN, STN, FSTN Technology - Display layout

Icons, alphanumeric, dot-matrix graphic - Resolution

Up to 640x480 dots - Glass thickness

0.3mm, 0.4 mm, 0.55mm, 0.7mm, 1.1mm - Other Special features

Field Sequential Color (FSC) LCD, Color TN LCD, Enhanced Black TN (EBTN), Color Printing LCD, High contrast negative LCD, Fast Response LCD Module at Low Temperature Operation, Film LCD, Shaped LCD

Enhanced Black TN (EBTN)This display mode offers exceptional dark background because of its very low light leakage.

The contrast ratio is up to 1000:1, exceeds that of conventional TN, STN and FSTN. Besides, it offers 3 best viewing directions in one display, in contrast of one direction for conventional display. Furthermore, its wide operating temperature capability extends the range of applications, including automotives.

Applications:

|

Field Sequential Color (FSC) LCDThe backlight produces the fundamental colors R-G-B sequentially, the sequence is looped. A fast response LCD which is placed in front of the backlight is switched and acts as a light shutter that is controlling the brightness of each fundamental color.

|

Color TN LCD

Color TN LCD is different from conventional color printed TN negative display. It can show colored segments in white background with backlighting as a positive mode display. The LCD is transflective and the user can put color printing behind the LCD to give desired color performance. The additional feature is that its readability can be maintained when the backlight is off, but in grey or black patterns.

|

Color Printing LCD

|

High contrast negative LCD

|

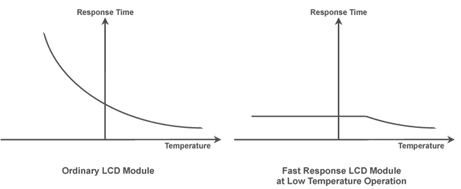

Fast Response LCD Module at Low Temperature OperationThe response time of LCD at low temperature, say -40¢XC, could be more than 1 minute. This could be a big problem in display application.  |

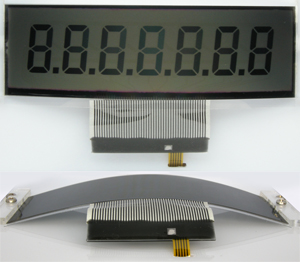

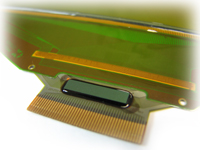

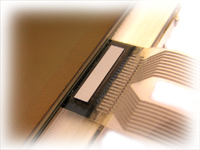

Film LCDFilm LCD is an ultra thin display (thickness is less than 1mm). A transparent plastic sheet is used as substrate that makes the film LCD be thinner and lighter than the conventional LCD glass panels. Film LCD features a substrate of flexible plastic which allow the display to be bent. The applications of handheld products such as watch , smart card or curve surface products can take the advantages of thin, light and flexibility of film LCD. In this stage, Clover focuses on small panel size(1"~4") and TN mode only.  |

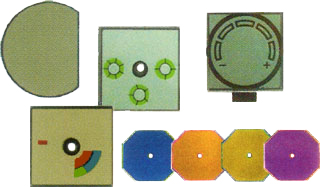

Shaped LCD

|

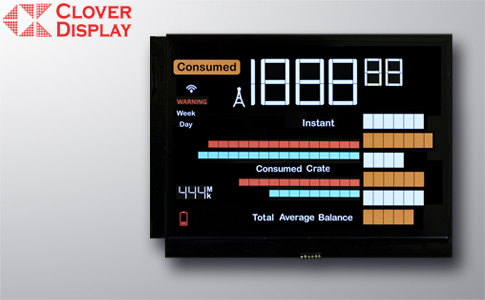

Custom Designed LCD Modules

- LCD Module circuit design for instruments, handheld products and consumer products

- Assembly technique

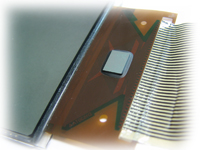

COF (Chip on Foil)

|

COG (Chip on Glass)

|

TAB (Tape Automatic Bonding)

|

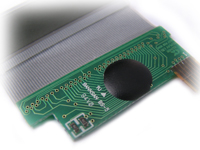

COB (Chip on Board)

|

SMT (Surface Mount Technology)

|

Backlight option

|

Touch panel

|

SSCT

|